Reserve your Moon Airbnb today

I have a vivid memory of watching the Apollo 11 launch from the shores of the Indian River

That was the iconic mission to the Moon with Neil Armstrong, Buzz Aldrin and Michael Collins on board.

Today, there is a new space race to get to Mars. And it will drive the next leap forward in technology.

Taller than the Statue of Liberty, the sheer size and power of the Saturn V rocket left me in awe as it slowly but steadily climbed toward the heavens. Nasa developed it specifically for the moon launch. Its payload dwarfed all the previous rockets up to that point.

As a kid, it was a profoundly moving and unforgettable experience. The launch of the rocket filled me with pride and wonder as it also launched the era of space exploration. This was the American spirit made real. We were the first to go to the moon.

I insisted on having Tang every morning.

Since then, NASA became the center of space exploration. It was an incubator for innovation and new technology. The space program’s commitment to advancing technology profoundly impacted our daily lives. Things like scratch resistant lenses, ear thermometers, shoe insoles, cordless tools, satellite navigation, memory foam, and even the material used to make invisible braces all come from the space program.

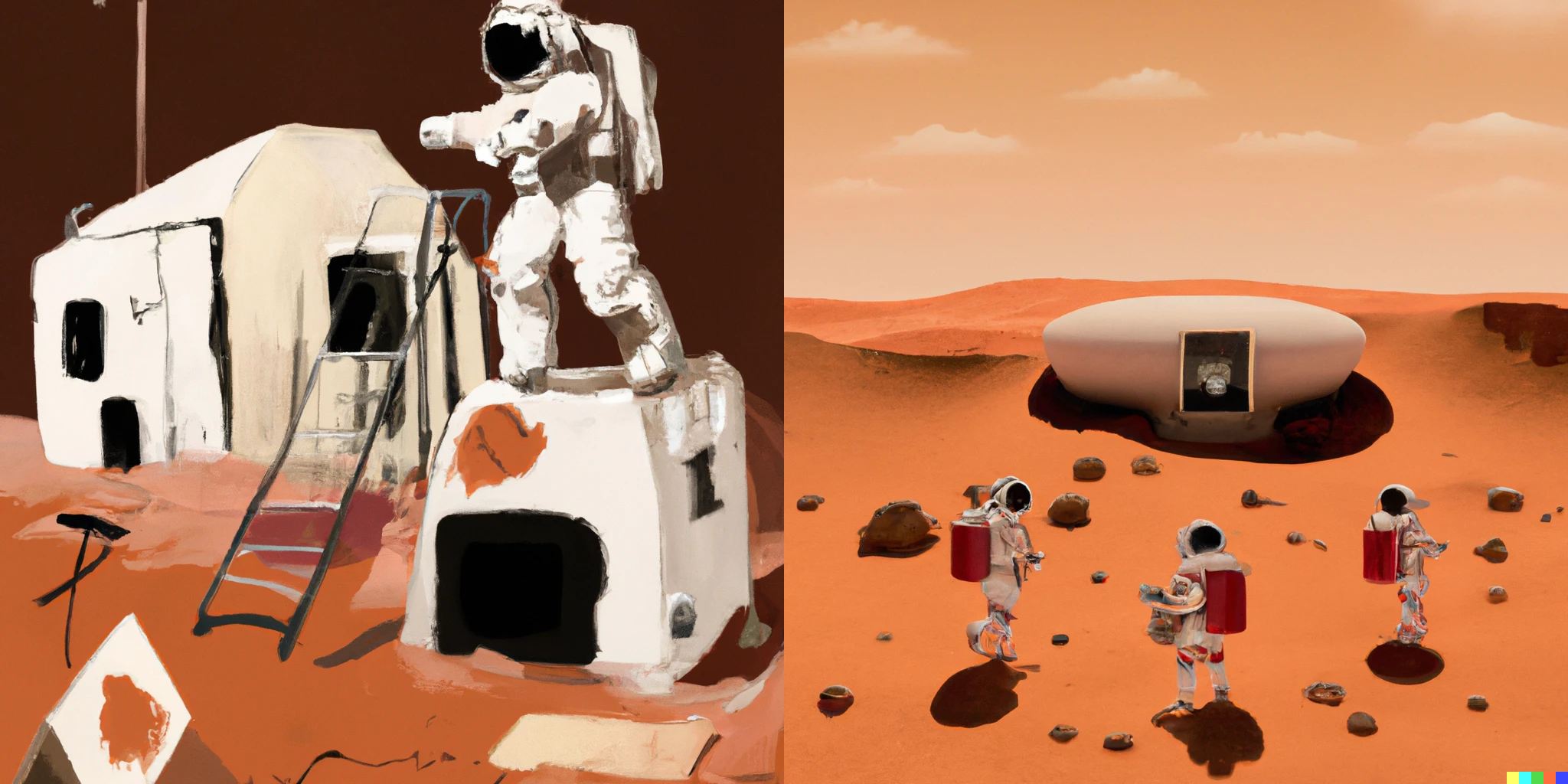

Today, the space program now pivots to the red planet, Mars. And once again, we need for a host of new technological advancements to support the mission. This endeavor is an unprecedented challenge.

The Mars mission is way more complex than reaching the Moon. The moon is 239,000 miles from earth. Mars is 238 million miles from earth.

That’s why we’ll need a pit stop.

The path to Mars goes through the Moon. The Moon will serve as a testing ground and the gateway to Mars.

One critical test will building working and living structures. There is no Home Depot on the Moon (yet). But there is an emerging and innovative solution to the unique challenges of lunar habitation.

For Icon Technology the concept of 3D printing habitats on the Moon is not science fiction. It is an exciting venture that holds the potential to revolutionize space exploration and the future of human habitation beyond Earth. We wrote about this company previously here on The Grove about the good it can do here on Earth.

NASA recently awarded ICON Technology a $57.2 million dollar contract to develop construction technologies that could help build infrastructure such as landing pads, habitats, and roads on the lunar surface.

The Challenges of Lunar Colonization

Establishing a sustainable human presence on the Moon presents numerous challenges, including:

- Extreme Environments: The Moon’s environment is harsh, with extreme temperatures, elevated levels of radiation, and the absence of a breathable atmosphere.

- Cost and Resource Limitations: Transporting construction materials and equipment from Earth to the Moon is prohibitively expensive. Hence, lunar habitats must make efficient use of local resources.

- Sustainability: Sustainable lunar colonization demands minimizing waste, maximizing resource utilization, and reducing environmental impact.

- Rapid Construction: The ability to construct habitats quickly is crucial for crew safety and mission success.

This is where ICON Technology’s 3D printing comes in.

3D printing offers several advantages when it comes to building on the Moon:

- Resource Utilization: One of the most significant benefits of 3D printing lunar habitats is the ability to use local resources. Lunar regolith, a layer of loose, rocky material covering the Moon’s surface, makes a good raw material for 3D printing.

- Customization and Efficiency: 3D printing allows for the creation of customized, intricate designs. It can produce habitats precisely tailored to the specific needs of lunar residents.

- Minimal Waste: Traditional construction methods generate significant waste, which is not sustainable for long-term habitation. 3D printing generates little to no waste, as it uses a layered approach to construction.

- Rapid Deployment: The quick construction process of 3D printing means less time for the crew to be at risk.

Moving to The Moon

3D printing lunar habitats represents a bold step toward making lunar colonization a reality. By leveraging lunar resources, optimizing design, minimizing waste, and speeding up construction, this technology will be instrumental for lunar colonization.

While there are still challenges to overcome, recent progress highlights how 3D printing may help humanity live and work on the Moon.

So, reserve your Moon lot now won’t be long before you can start building your Moon vacation cottage.

For The Good

Michael Nichols

Numbers to Know

15%

At liftoff, the Artemis produces 15% more thrust than the Saturn V rocket. For more comparison on then and now of these rockets click here. (NASA)

1981

The year of the first 3D printer when Hideo Kodama was trying to find a way to develop a rapid prototyping system. He came up with a layer-by-layer approach for manufacturing, using a photosensitive resin that was polymerized by UV light.(BCN3D)

$300,000

The cost of the first 3D printer, the SLA-1 went on sale in 1988. Today you can pick one up on Amazon for under $500. (3D Print Spy)

What’s New in Sustainable Investing

3D Printer Manufacturing in the US – Market Size, Industry Analysis, Trends and Forecasts (2023-2028)

3D printer manufacturers have enjoyed massive organic growth over the past five years, and revenue has climbed at a CAGR of 14.6% to $7.7 billion, including 19.1% growth in 2023 alone. (IBISWorld)

Embracing the future: the intersection of fintech and sustainable investing

The surging interest in sustainable investments is not matched by the technological infrastructure within the fintech sector. While consumers are drawn towards aligning their investments with their values, the platforms and tools are not adequately equipped to support this trend. (Fintech Futures)

Video Of The Week

… 5, 4, 3, 2, 1, Liftoff

Rarely is there a moment when the entire world is fixated on one event. The Apollo 11 launch was one of those moments.